Ayako Yamada一百二十三,Jean-Louis Viovy一百二十三,Catherine Villard一百二十三和圣_潘尼除垢剂一百二十三

一居里物理实验室,Institut CuriePSL Research University,CNRS UMR168,Paris,France.

二Sorbonne Universités,UMPC Univ.巴黎06,Paris,法国

3皮埃尔·吉勒斯·德根尼斯研究所,Paris,法国

Email: ayako.yamada@curie.fr

Why is this useful?

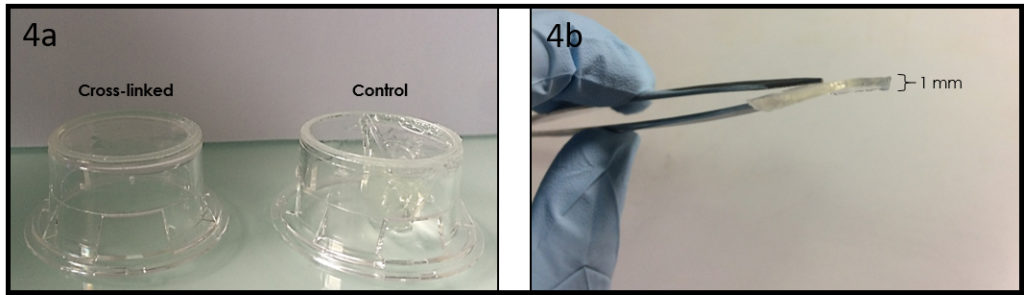

玻璃是一种多用途的化学处理表面,它仍然是迄今为止最常用的表面工程基板(例如micropatterning,surface 新利手机客户端chemistry) or plasma-bonding of PDMS microfluidic devices.在这种基质上进行细胞培养,玻璃底培养皿是为了保持细胞外明确的培养基体积,保护细胞免受污染和介质蒸发。Moreover,它们在光学上比通常用于细胞培养的聚苯乙烯培养皿更适合显微镜观察。Although glass-bottom culture dishes are commercially available (e.g.来自WPI的荧光皿)the presence of plastic walls limits the treatments that can be performed onto the glass bottom surface and those are more expensive ( 5 € per dish;φ 50 mm) than polystyrene dishes (e.g.φ 40 mm dish from TPP,0.5 € per dish).在这个提示中,we describe an easier way than a previous Tip一把聚苯乙烯培养皿变成玻璃底培养皿,同时保留了在玻璃装配成盘子之前对其进行任何处理的可能性。Note that in this method,the body of the culture dish will be upside down and the lid is thus no longer lifted above the dish opening by lid stoppers.然而,the gas exchange through the gap between the body and its lid seems to be enough to culture cells healthily in this dish.In summary,this Tip provides a low-cost and rapid solution for cell culture in a microfluidic device or on an engineered surface directly in a culture dish,suited for a long-term live cell imaging.

What do I need?

- φ 40 mm polystyrene tissue culture dish (e.g.TPP #93040)

- φ40 mm盖板滑块(例如Thermo Fisher Scientific #11757065,每张幻灯片~0.2欧元)

- Large screw driver (or a similar tool)

- PDMS基和固化剂的未固化混合物(10:1 w/w)

- 烤箱或热板

- Ferromagnetic metal plate (e.g.PDMS容器盖,optional)

- Cylindrical magnets (optional)

What do I do?

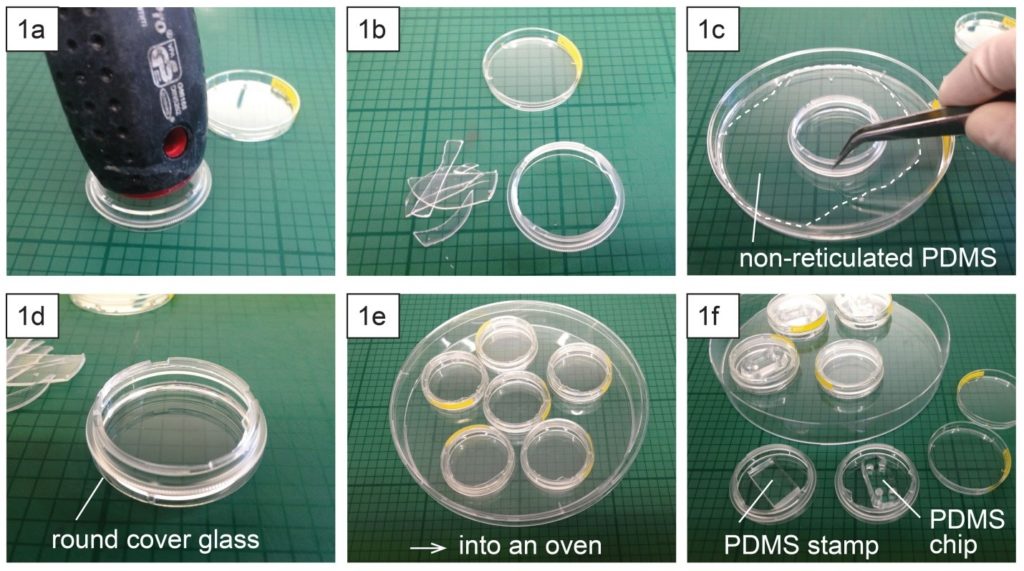

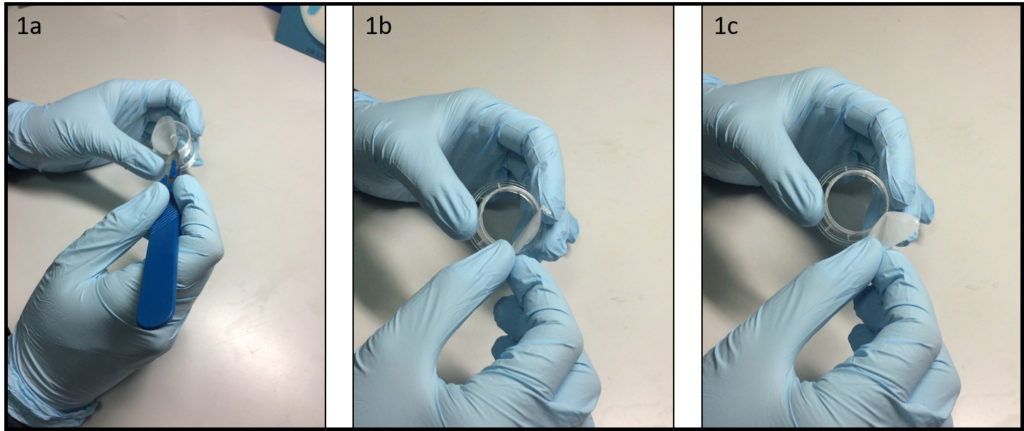

- Place a polystyrene culture dish upside down on a surface and hit a few times the center of the dish bottom with the grip of a large screw driver (Fig.1a) until the dish bottom falls apart from the dish wall (Fig.1b)。成功率在9%到10%之间时,底部应该容易下降。Avoid breaking the dish wall by hitting the bottom too strongly.

- Spread uncured PDMS mixture on a flat substrate (e.g.一个较大的塑料培养皿),并在培养皿边缘(破碎部分)涂上PDMS(图1c).

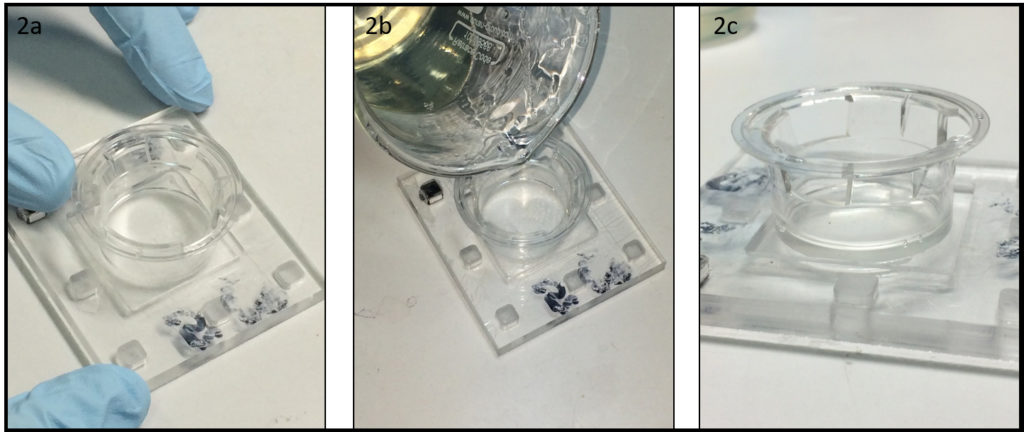

- Place the dish (broken part up) on a cover glass slide (Fig.1d) and cure PDMS in an oven or on a hotplate e.g.在80°C下保持10分钟(图1e).

- 表面处理(例如micro-contact printing) or plasma-bonding of a PDMS chip to the glass surface can be performed after or before the dish assembly (Fig.1F)。

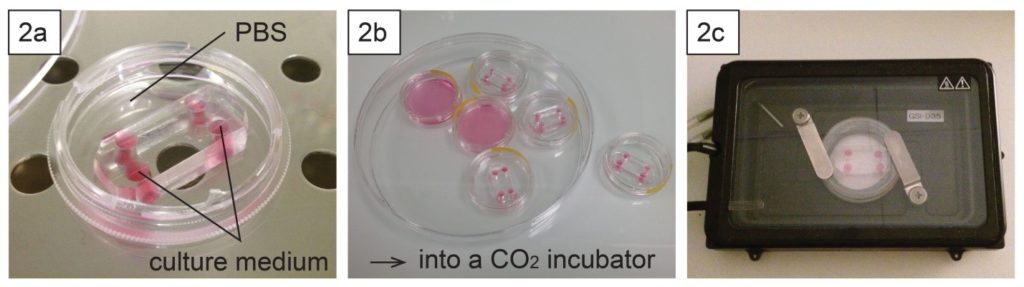

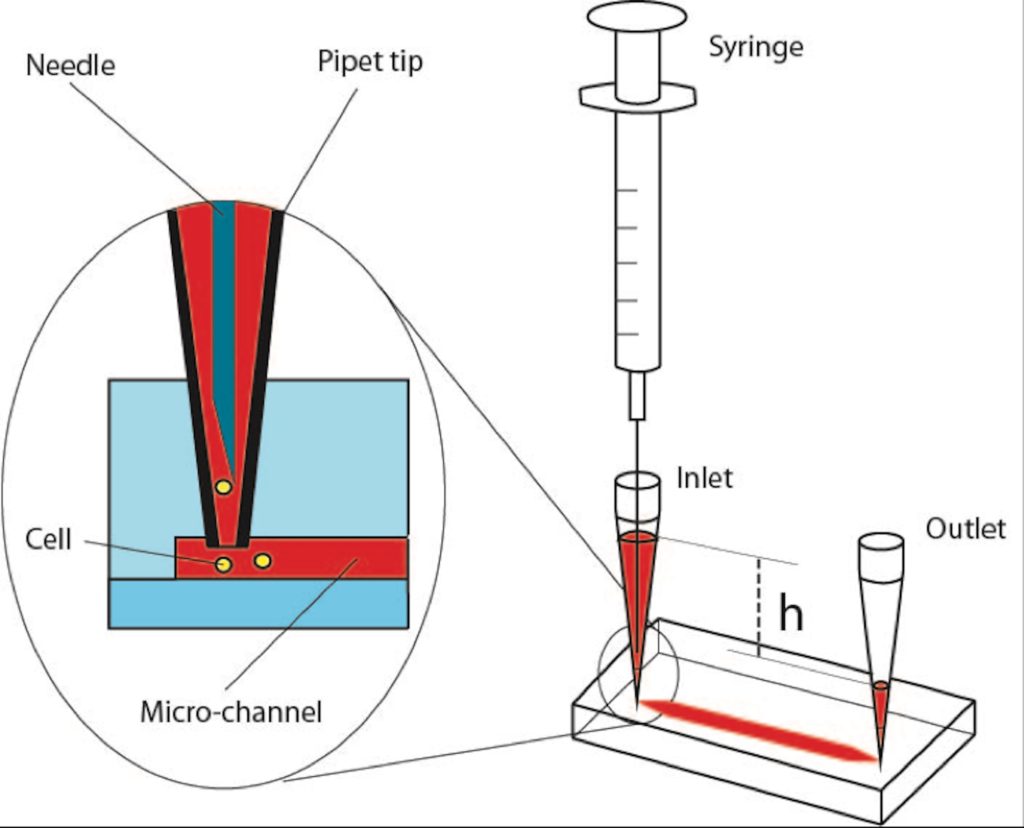

- 为了保持片上细胞培养的湿度,这道菜可以用例如phosphate buffered saline (Fig.2a).装有芯片或微电池的盘子可以放在一氧化碳中。二有或无进一步保护的孵化器(图2b).

- Long-term live cell imaging can be performed using a stage top incubator (Fig.2C)。

我还应该知道什么?

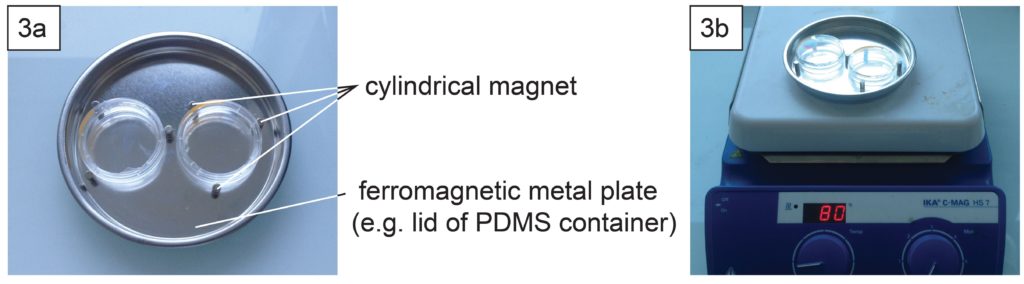

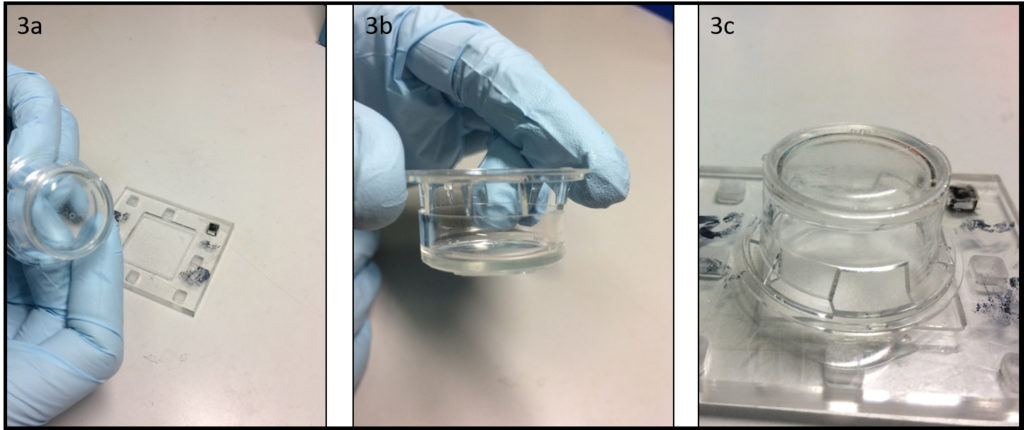

- 根据显微镜的支撑类型,it might be necessary to well align the contours of the dish and the glass slide.这可以使用圆柱形磁铁(每盘3个)和铁磁金属板(图3a)在烤箱或加热板上进行PDMS固化时(图3b)。

确认

这项工作得到法国国家研究机构(ANR)的支持,作为“Avenir投资计划”(参考号:ANR 10-nano 0207)和ERC高级赠款大提琴(FP7-IDEAS-ERC-321107)的一部分。

参考文献

[1] Caballero D,Samitier J为活体细胞成像研究制造细胞培养室的不同策略。Chips and Tips,2014年12月2日(//www.xcmww.com/chipsandtips/2014/12/02/different-strategies-for-the-fabring-of-cell-culture-chambers-for-live-cell-imaging-studies/)