明知基姆a,石观亚乙,潘明c,Lucas R.布劳赫a,and Sindy K.Y.唐a*

aDepartment of Mechanical Engineering,斯坦福大学,斯坦福大学,CA 94305,美国

乙Undergradute Visiting Research Program,工程学院,斯坦福大学,斯坦福大学,CA 94305,美国

c材料科学与工程系,新利手机客户端斯坦福大学,斯坦福大学,CA 94305,美国

为什么这个有用?

许多生物和化学制备过程都需要离心步骤。The transfer of samples between the original sample container and tubes required by commercial centrifuges increases the risk of sample contamination,and often leads to the loss of samples.商用离心机在实验室以外也不容易买到。在这里,我们展示了一个简单的3D打印支架的设计,用于连接我们用作离心机的电钻/驱动器的夹头。这种方法的优点包括:1)支架可以设计成容纳非常规容器(例如,syringes,glass vials,毛细血管)2)电钻/驱动器比离心机更广泛。我们展示了各种样品(例如,water-in-oil emulsions,细胞悬浮液,food and drinks,wet soil) in various containers can be centrifuged with our method.This method should be useful for field work outside of the laboratory,对于更广泛的DIY社区,对需要离心的家庭应用感兴趣,such as blood separation and related diagnostics,从湿土中分离间隙水进行污染检测,食品样品中过敏原的提取和鉴定,and fluid clarification (e.g.,橄榄油,葡萄酒)通过加速沉淀。

What do I need?

- 电钻/驱动器(Dewalt DC742KA无绳紧凑型电钻/驱动器套件[1])。

- 3D-printed custom holder.

- 3D打印的钻头/驱动器自定义支持。

- 4支1毫升注射器(标准注射,Part No.: 4010-200V0) as an example of non-conventional sample containers.

- 一个长螺栓(盘头机螺钉,锌,#8 x 1-1/4") and one matching nut (Hex Nut,锌,#8-32).螺栓的尺寸应与钻头/驱动器的夹头匹配。

- Four short bolts (Pan Head Machine Screw,锌,#6 x 1/2”)以将1毫升注射器固定到3D打印定制支架上。

What do I do?

- 使用SolidWorks或其他CAD软件设计自定义支架。

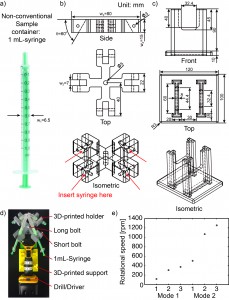

- 测量外径(W一=6.5 mm)1 ml注射器(图2a)。我们在确定槽的宽度时包括了0.5 mm的公差(W2=7 mm),1 ml注射器将固定在其中(图2b)。

- 确定1毫升注射器相对于旋转平面倾斜的角度(Q=60°)。

- Decide the length (w3= 80 mm) and the thickness (w四=15 mm)。

- 测量或识别短螺栓和长螺栓的外径,并分别对f3和f5使用这些值。

- Design a custom support for the drill/driver (Fig.2C)。The dimensions of this support are not critical so long as the drill/driver 在操作过程中稳定且不翻倒。

- 3D-print the holder and the support.我们使用了Robo 3D的3D打印机[2]。XYZ方向的3D打印机分辨率为100 mm。我们使用的材料是聚乳酸(PLA)。

- Assemble the centrifuge (Fig.2d).

- 将一个长螺栓穿过支架中心,并用螺母拧紧。

- 将螺栓插入钻头/驱动器的夹头中,通过推动钻头/驱动器的扳机几次拧紧螺栓。

- Make sure the bolt is fixed in the chuck and aligned to the drill/driver.

- Place the drill/driver in the 3D-printed support.

- Secure four 1 mL-syringes to the holder using the four short bolts.

- 按下钻机/驱动器的扳机5-10分钟,启动离心机。The plane of rotation should be parallel to the floor.

- 拧下短螺栓以拆下注射器。

- 如果需要,measure the rotational speed of the drill/driver before inserting the real samples.我们在iPhone中使用slo-mo模式来校准钻头/驱动器的转速[3](图2e).

- Results (Fig.3).

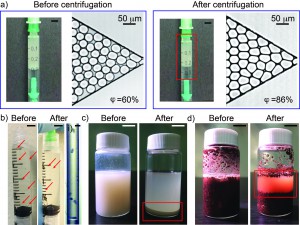

- Water-in-oil emulsion: Micron-sized uniform water-in-oil droplets were collected in a 1 mL-syringe.After a needle was connected to the syringe,注射器固定在3D打印支架上,针头朝上。在离心分离之前,将另一个含有等量液体的注射器添加到支架的另一侧,使支架保持平衡。We centrifuged the sample at a speed of 374 rpm for 10 minutes.然后将液滴注入微通道,测量离心前后体积分数的变化。体积分数定义为水滴总体积与充满通道的流体总体积之比。离心后,the volume fraction of the emulsion increased from 60% to 86% without a change in the size of the droplets.Neither break-up nor coalescence of the droplets was observed.

- 斯托托尔 coeruleus:为了证明细胞悬浮液的浓度,我们用过斯托托尔 coeruleus(www.carolina.com) as a model.We filled a 3 mL-syringe with about 20斯托托尔cells suspended in 2 mL of aqueous culture media (concentration ~ 10 cells/mL).将针头连接到注射器,然后将注射器固定在3D打印支架中,使针头朝下。细胞悬浮液以374转/分的速度离心5分钟。The cells were concentrated at the bottom,靠近针的入口。然后可以通过针头将这种浓缩细胞悬浮液注入聚乙烯管中。Fig.2-i) shows the microscopic image of the cells in about 15 mL of aqueous culture media in the tubing (concentration ~ 400 cells/mL).

- Korean rice wine (Makgeolli): A separate holder was designed to hold a 20 mL-glass vial.小瓶内装12毫升韩国米酒,以1252转/分的速度离心10分钟。The sediment was clearly observed after centrifugation.On the other hand,the sediment was not observed for more than 20 minutes without centrifugation.

- 湿土:以1252转/分的速度将10毫升湿土在20毫升玻璃瓶中离心10分钟。从土壤中分离出间隙水。

图2。1毫升注射器作为非常规容器。b) Drawing of 3D-printed holder generated by SolidWorks.c)SolidWorks生成的3D打印支架图纸。d)实验装置照片。The 3D-printed holder was connected to the drill/driver placed on the 3D-printed support.Four 1 mL-syringes were then tightened using the short bolts.e)不同钻机/驱动器模式下转速与触发水平的校准图。模式1和模式2指示钻机/驱动器变速箱中的不同档位设置。The numbers 1 to 3 in each mode indicate user-defined trigger levels.转速范围从120转/分到1252转/分。The rotational speeds were measured using SLO-MO function in iPhone 6.

图3。a)1毫升注射器中的乳剂照片和离心前后注入微通道的乳剂显微图像。照片中的比例尺是5毫米。b)的照片斯托托尔离心前后3ml注射器中的细胞。红色箭头表示单个单元格。The scale bar is 5 mm.i) Microscopic image of 6 Stentor cells in a polyethylene tubing after centrifugation.The scale bar is 300 mm.c)离心前后20毫升玻璃瓶中韩国米酒的照片。红色框表示沉积物。比例尺为10毫米。d)离心前和离心后20毫升玻璃瓶中的湿土照片。红框显示从湿土中分离出的间隙水。比例尺为10毫米。

我还应该知道什么?

- The centrifugal force can be increased by lengthening the arms (w3)拿着容器。

- 可使用高速摄像机或具有慢动作录像功能的智能手机测量转速,因此,帧速率足以满足所用的转速。

- The load in the centrifuge should be balanced.

- For safety purposes,应佩戴护目镜。离心机也应放置在安全屏障内(例如,a sturdy laundry basket).还应遵守钻机/驾驶员的安全说明。

- 离心10分钟后,我们发现钻头/司机开始发热。If centrifugation time longer than 10 minutes is needed,应该可以执行多轮10分钟离心步骤,中间休息,以冷却钻头/驱动器。

Conclusion

In this work,we demonstrated that 3D-printed holders attached to an electric drill/driver can be used for the centrifugation of samples in non-conventional containers.As 3D-printers and hand drills are easily accessible,我们希望这条建议能在实验室外的现场工作环境中立即得到应用,也可以在家为DIY用户。

Acknowledgements

我们承认斯坦福森林环境研究所和国家科学基金会的支持(奖项1454542和1517089)。新利手机客户端

References

1。http://www.dewalt.com/products/power tools/drills/drills and hammer drills/12V–38-10MM-cordless-compact-drilldriver-kit/dc742KA

2。http://store.robo3d.com/collections/all/products/r1-plus-3d-printer?变量=6274616835

三。http://www.imore.com/how-to-record-video-iphone-ipad